Flame Retardant OP1312 OP1314 for PA6 PA66

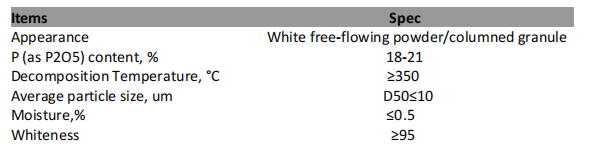

Technical Data:

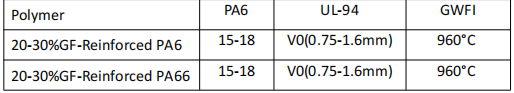

Recommended dosage:

Processing instruction:

1. Pre-drying the polyamide,the moisture content should be below 0.1 % (by wt.).

2. The optimum conditions for incorporating should be determined in each individual case. Care must be taken to ensure homogeneous dispersion of all components.

3. The temperature of the polymer melt should not exceed 350 °C.

4. It is most suitable for equipment with weak shear force.

5. The processing temperature of Parallel twin-screw extruder should keep between 210 ~ 245 ℃ with vacuum at the same time.The temperature is too high, the physical property loss of PA6 is large, and the yellowing is also large.

6. Do not use low-alkali or high-alkali fiberglass. High-quality non-alkali fiberglass is preferred.

Package & Storage:

Net weight 25KG Kraft bag with PE liner.